Electric butterfly valve (also known as flap valve) is a regulating valve whose closing part is annular disc or disc plate. The key is composed of oil circuit plate, valve rod, butterfly plate and sealing ring. The oil circuit plate is cylindrical with short radial length and embedded butterfly plate. The butterfly plate of the butterfly valve is installed in the diameter direction of the pipeline. In the cylindrical safety passage of the oil circuit plate of the butterfly valve, the disc-shaped butterfly plate rotates around the center line with a rotation angle of 0 ° ~ 95 ° in the middle. When it rotates to 95 °, the gate valve is fully opened.

The electric butterfly valve has the advantages of simple structure, light weight and light weight. It is only composed of a few parts. It can only be opened and closed quickly by turning 95 °, which is convenient to use. Together, the gate valve has excellent fluid control characteristics. When the butterfly valve is in the fully open position, the thickness of the butterfly plate is the only friction resistance when the material flows through the oil circuit plate. Therefore, according to the small gas pressure caused by the gate valve, it has good flow monitoring characteristics. Butterfly valve has two sealing forms: elastic sealing and metal material sealing. For ductile sealing gate valve, the sealing ring can be embedded on the oil circuit plate or attached near the butterfly plate.

The sealing butterfly valve made of metal materials usually has a longer service life than the ductile sealing butterfly valve, but there is no way to ensure the complete sealing. Metal material sealing butterfly valve can integrate higher operating temperature, while ductile sealing butterfly valve has the disadvantage of being limited by temperature.

If the electric butterfly valve is specified as a flow monitoring application, the key is to properly select the valve size and type. The basic principle of making a large-diameter butterfly valve is to make a suitable valve. Butterfly valves are not only used in common industrial production such as crude oil, liquefied gas, chemical plants and sewage treatment, but also used in the cooling system of thermal power plants.

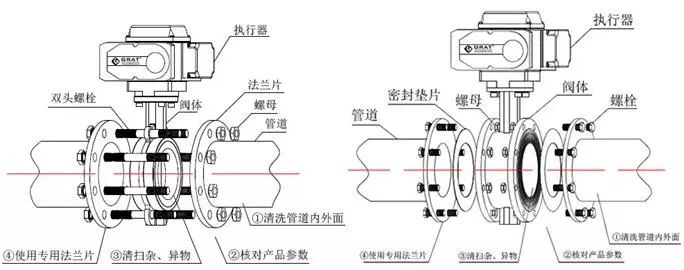

Common electric butterfly valves include wafer butterfly valve and flange butterfly valve. The wafer butterfly valve connects the gate valve between the two pipeline flanges with stud bolts. The flange butterfly valve contains a flange on the gate valve, and the looper flanges on both sides of the gate valve are on the pipeline flange with anchor bolts.

Preparation before installation of electric butterfly valve

Note: 1. After unpacking, the valve shall be installed in time. Do not loosen any fastening screws or nuts on the valve at will;

2. The electric butterfly valve can be installed on the pipeline at any angle. In order to facilitate maintenance, it is recommended not to install it upside down.

3. When installing the butterfly valve flange, ensure that the flange surface is aligned with the sealing rubber, the screws are tightened evenly, and the sealing surface must fit completely; If the screws are tightened unevenly, the rubber protrusion will jam the butterfly plate, or the valve rod will leak against the butterfly plate.

Installation steps of electric butterfly valve

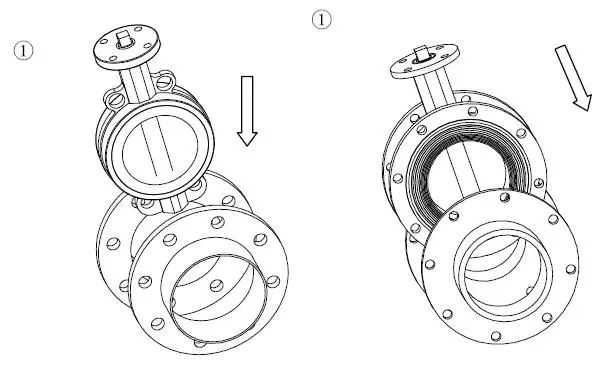

1. Place the valve between the two pre installed flanges (the gaskets at both ends of the flange butterfly valve need to be pre installed);

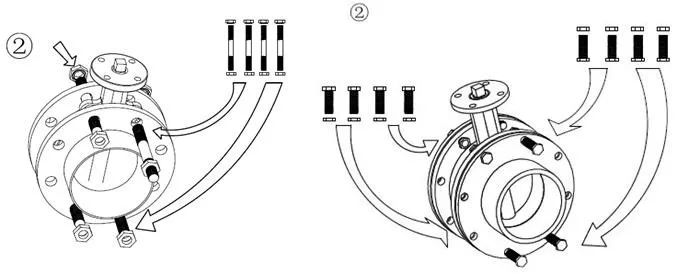

2. Insert the bolts and nuts at both ends into the corresponding flange holes at both ends gently as shown in the figure (the gasket position of flange butterfly valve needs to be adjusted), and tighten the nuts slightly to correct the flatness of the flange surface;

3. Fix the flange on the pipe by spot welding;

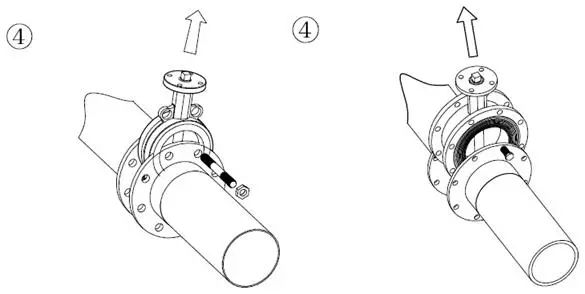

4. Remove the valve;

5. Completely weld and fix the flange on the pipe;

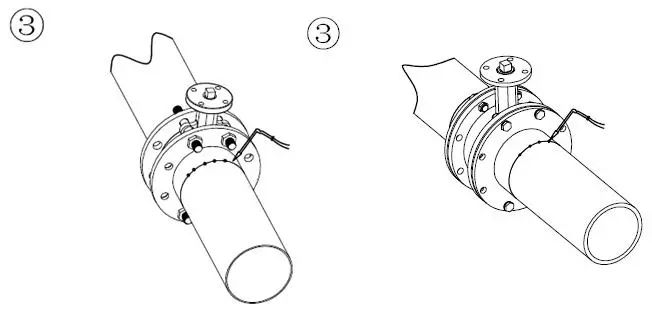

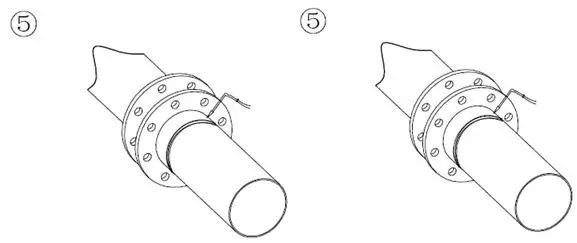

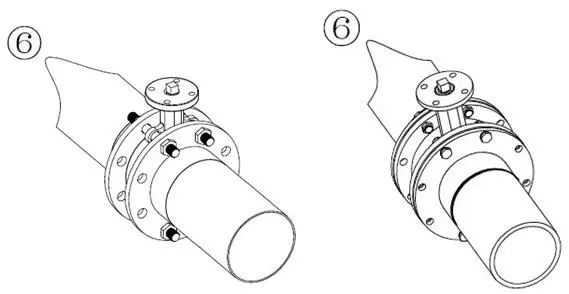

6. Install the valve after the welded junction cools down, ensure that the valve has enough moving space in the flange to prevent the valve from being damaged, and ensure that the butterfly plate has a certain opening (the flange butterfly valve needs to be sealed with gaskets); Correct the valve position and tighten all bolts (be careful not to tighten too tightly); Open the valve to ensure that the valve plate can open and close freely, and then open the valve plate slightly;

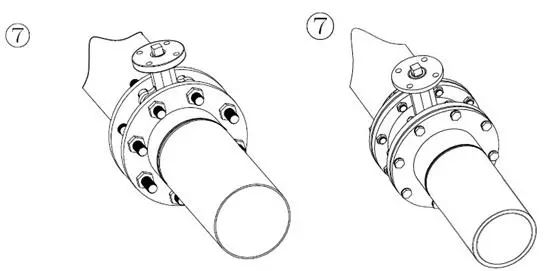

7. Tighten all nuts in cross balance;

8. Re confirm that the valve can open and close freely. Note: confirm that the butterfly plate does not touch the pipeline.

Note: the opening and closing stroke of the control mechanism has been adjusted when the electric butterfly valve leaves the factory. In order to prevent the wrong direction when the power is connected, the user should manually open it to half (50%) position before connecting the power, then press the electric switch, check the switch, check the direction of the steering wheel and the opening direction of the valve.

Tel:086-0531-81754461

Email: aimige@aimige.com.cn

Add:Room 1510, Huiyuan Building, No. 38 Huaneng Road, Lixia District, Jinan City, Shandong Province

Website: www.world-people.cn